Quality Policy

At Speedofer Components Pvt. Ltd., our commitment to excellence is reflected in our Quality Policy. We are dedicated to manufacturing products that align with the specific requirements of our customers. Additionally, our pledge extends beyond the production phase, as we are equally devoted to providing outstanding after-sales service. We believe in achieving this through a continuous process of improvement within our Quality Management system.

Quality Objectives

Our pursuit of excellence is guided by specific Quality Objectives, including :-

Adapting to Changing Technology :- We are committed to staying

abreast of the ever-evolving technology landscape in the soft ferrite core industry. This

commitment drives us to continually enhance our Quality Measurement System to meet the

challenges posed by changing technologies.

Continuous Improvement :- Embracing a philosophy of continuous improvement, we strive to refine and enhance our processes to ensure the highest quality in our soft ferrite core products. This dedication is pivotal in maintaining our position at the forefront of technological advancements.

Company Philosophy

At Speedofer Components Pvt. Ltd., our Company Philosophy revolves around the principles of

continual improvement and adapting to technological changes in the soft ferrite core

industry. We emphasize the creation of a healthy working environment for our employees and

nurturing strong relationships with our business partners.

In essence, our Company Philosophy encapsulates our commitment to growth, innovation, and

the creation of a positive and sustainable impact within the soft ferrite core industry.

Speedofer Components Pvt. Ltd. is dedicated to being a dynamic force that embraces change,

ensures quality, and builds lasting relationships.

Definitions & Equations

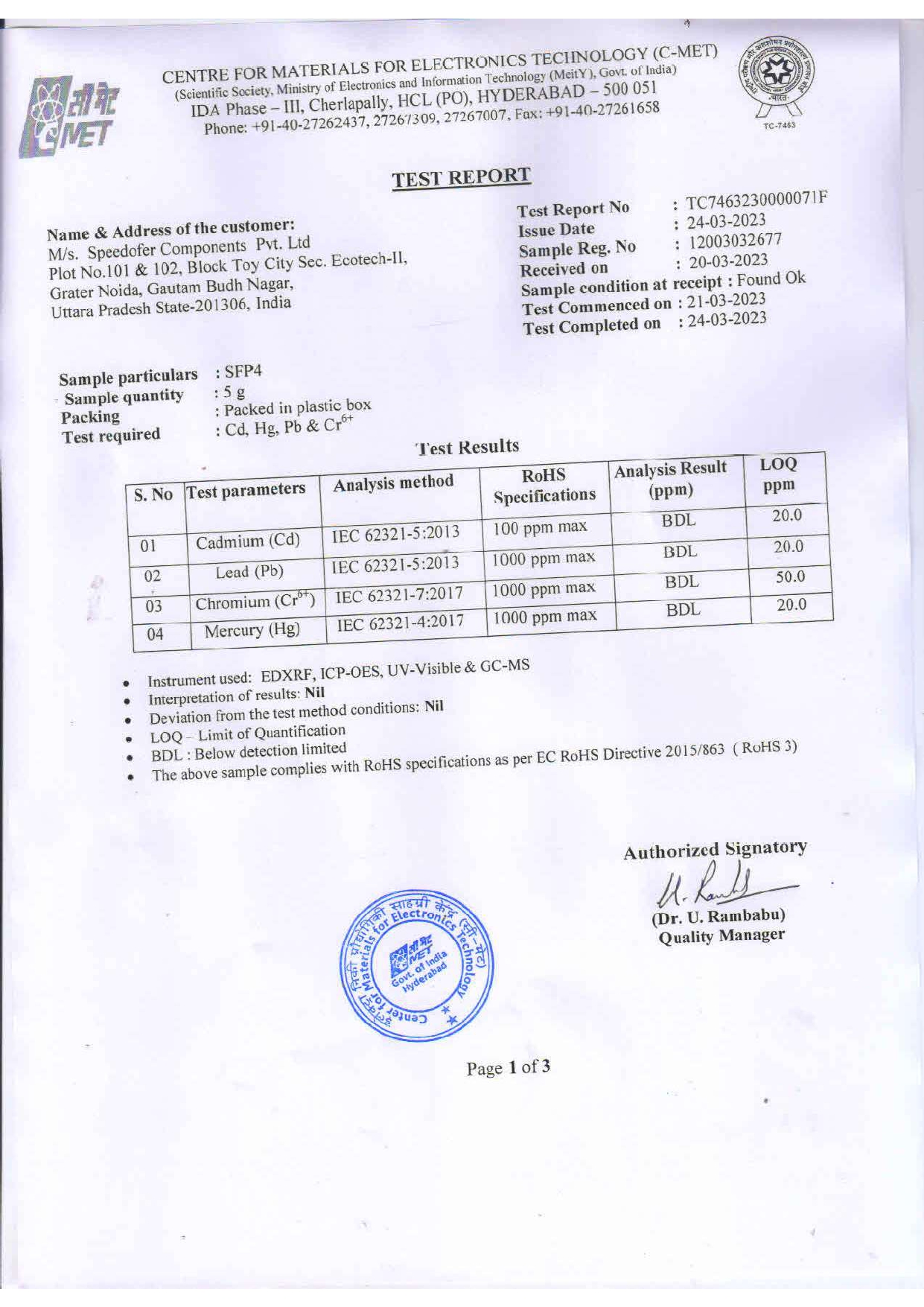

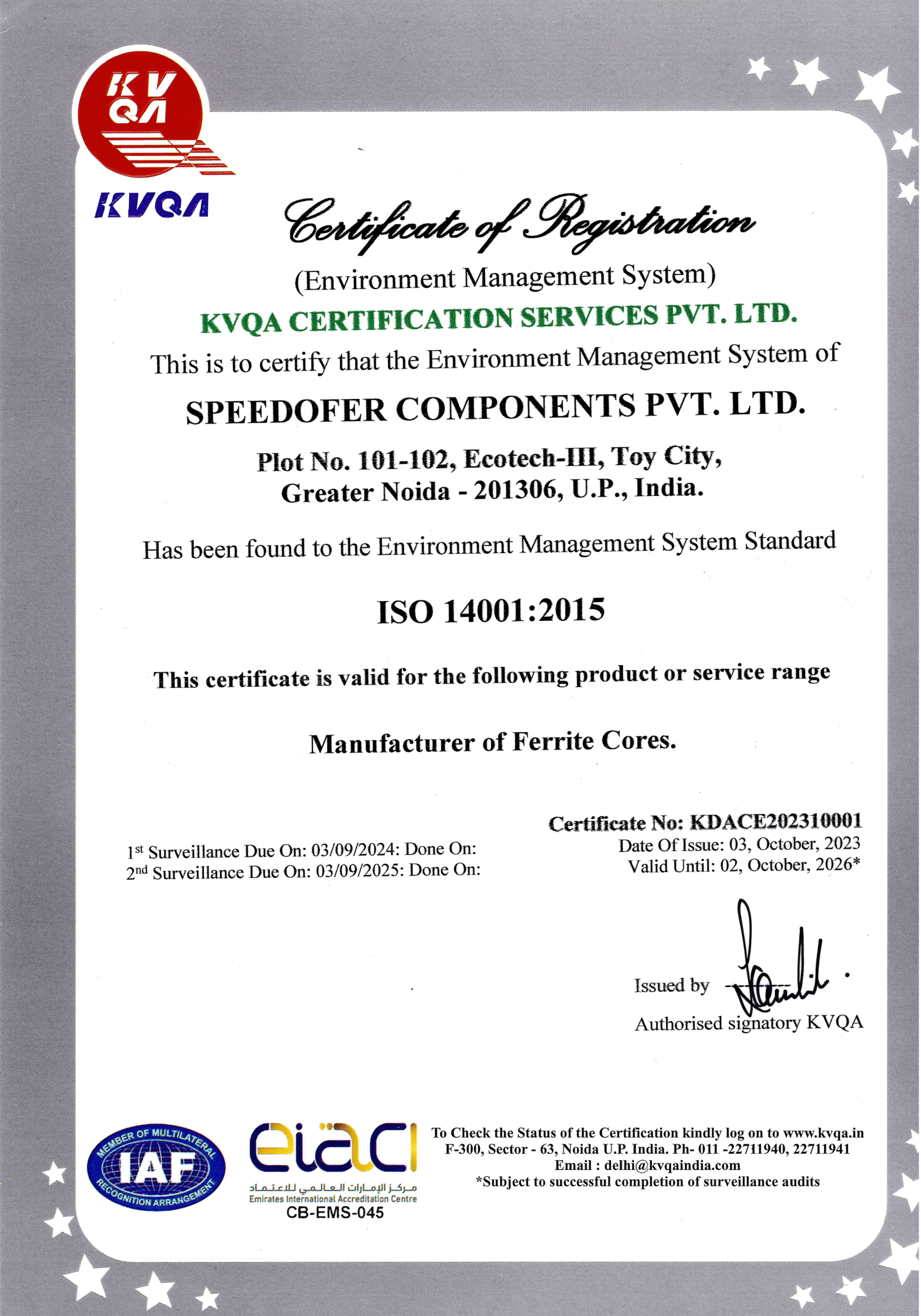

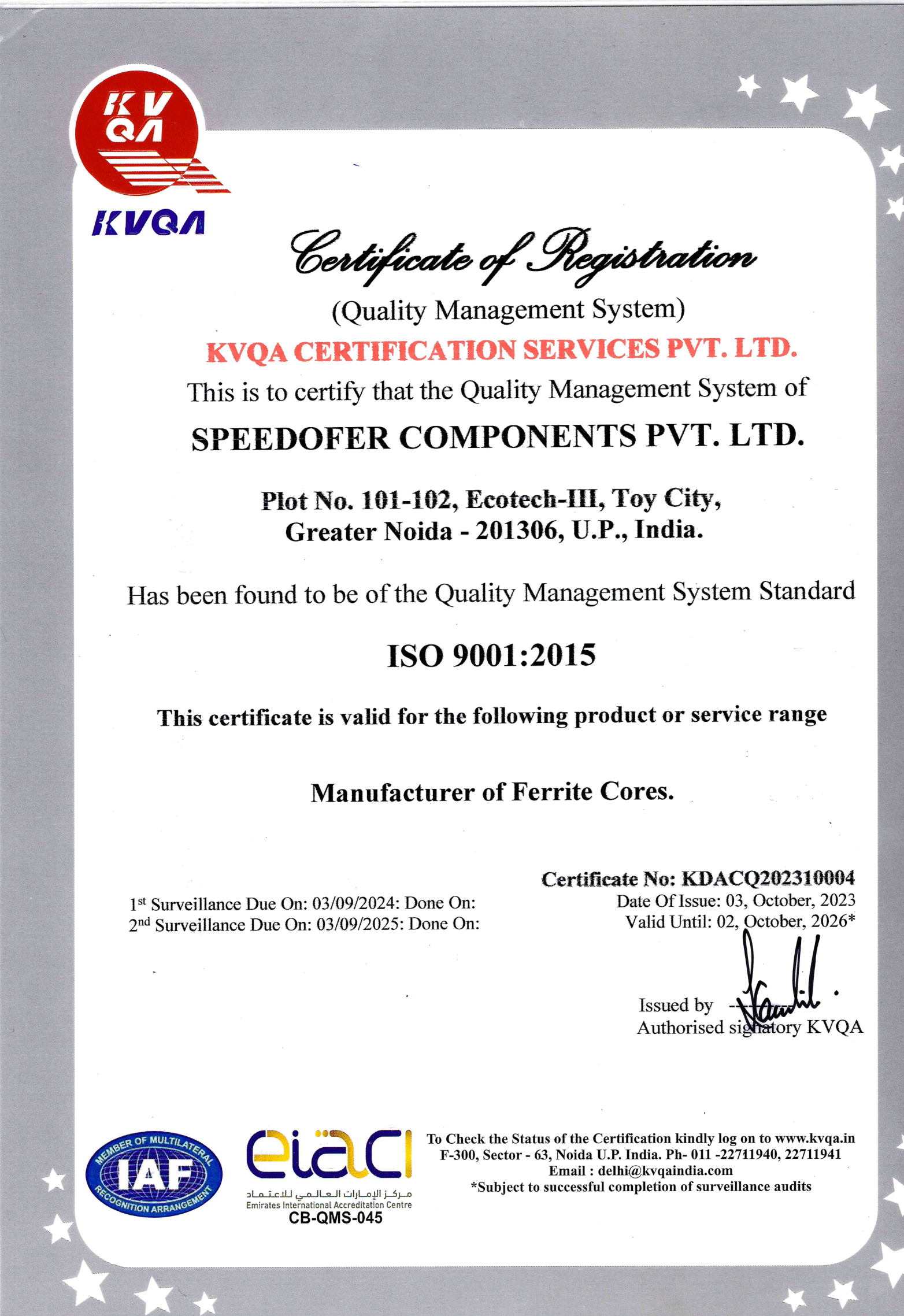

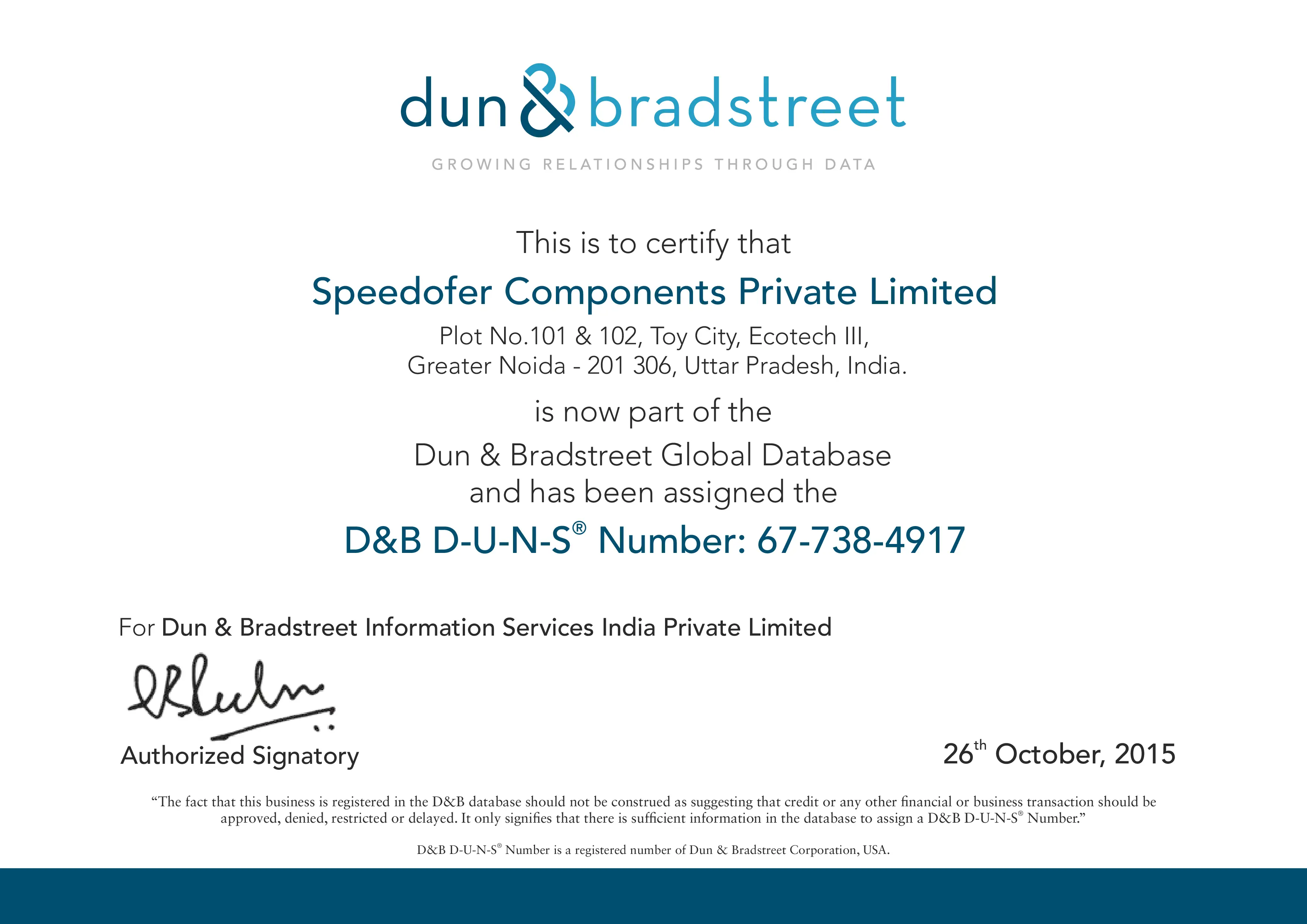

Speedofer Certifications

OHSAS

EMS

QMS

DUNS

Material Characteristics

Material Characteristics